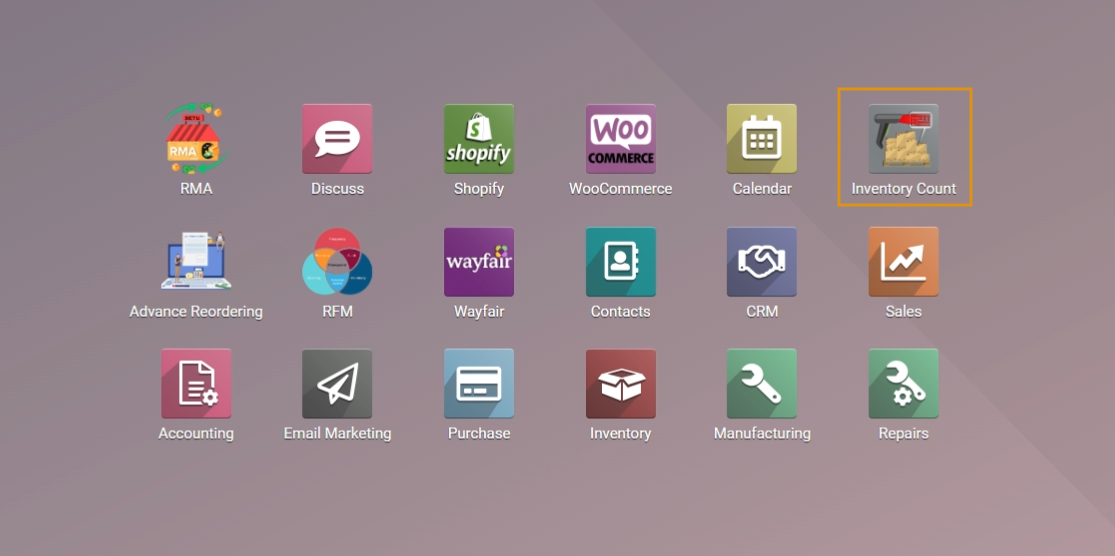

Getting Started

Getting Started

Inventory count is a dynamic solution that facilitates various Automated functionalities while Counting Inventory physically and helps to

=> Avoid Out-of-Stock and Over-Stock situations by facilitating Automated functionalities to sync the Physical Quantity of Products available in the store with the one in Inventory Management Software.

=> Ensure your store has the right quantity of products at the Right Place and Time.

=> Most User-friendly Facilitating Multiple Sessions

=> Various Reporting facilitating analysis over Performance throughput

Terminologies:

Inventory Count: Inventory Count allows a designated admin user or manager to create a physical count of the products for a specific warehouse or warehouse location. Also assign an approver, who has the authority to approve or reject the quantities counted by the user. This feature helps to ensure and track accurate inventory and its management for a particular warehouse and location that was assigned.

Inventory Count Planner: An Inventory Count Planner allows the scheduling of automatic inventory counts at regular intervals, without the need for manual intervention.

When should Inventory Count Planner be created?

Inventory Count Planner can be particularly useful for products that are in high demand and are important for your business. By scheduling regular, automated inventory counts, you can ensure that the inventory for these products is always up-to-date and accurate. This can help prevent stockouts, avoid overstocking, and ensure that you are always able to meet customer demand. Additionally, by identifying discrepancies early and addressing them quickly, you can improve overall inventory management and accuracy, which can help reduce costs and improve efficiency and customer satisfaction. The Inventory Count Planner eliminates the need for manual intervention, this allows the organization to focus on other important tasks and can be a time saver.

When should Inventory Count be created?

An inventory Count is a one-time manual count of the current stock levels, whereas an Inventory Count Planner automates the process of conducting inventory counts at regular intervals Inventory Count Planner allows for scheduled and regular checks of inventory levels to ensure accuracy, while a manual Inventory Count can be conducted as needed.

Inventory Count Sessions: Once the Inventory Count is created, an Inventory Count Session should be created to assign a User to physically count the products in the designated warehouse and location. This session will also be created by the Admin User of the manager to specify the User who will be responsible for performing the count. The User assigned to the session will go to the designated location and physically count the products and do entries of counted quantity in session through this solution, and once completed, the results of the count can be reviewed and approved by the assigned approver.

Commenting is not enabled on this course.